Frequently asked Questions

Concrete engineering advice

Business contact

How to check the concrete slump

Check slump at construction site

The slump test at the construction site is to check whether the concrete provided has the slump as committed in the contract (between the seller and the buyer) and in accordance with the technical documents prescribed for concrete used. at the construction site (given by the designing and project management side).

Technical aspect: Slump indicates the homogeneity of concrete and the proportion of components in the concrete mixture . Slump testing at site is a “quick test” of the quality of concrete provided.

The inspection must be conducted before deciding whether to allow the concrete vehicle (that batch of concrete) to be put into use (pouring into the components waiting for concrete placement). If the slump does not meet the commitment, the Investor should request that the concrete vehicle (that batch of concrete) be not put into use.

Steps to conduct sudden inspection and notes:

In essence, slump testing is a quality control method. For specific batches, the slump must ensure consistency. The change in slump height indicates an undesirable change in the ratio of the concrete mixture component and the subsequent ratio of the mixture is adjusted to ensure a consistent batch of concrete. This uniformity guarantees the improvement of the quality and integrity of the concrete structure of the concrete.

The concept: "Slump" is simply a term to describe how the concrete mixture stiffness, rather than using general descriptions such as "wetness" or "liquid". The height of the concrete mixture after being poured in cones decreases from one sample to another. Samples with lower heights are mainly used in construction, with high slump samples often used to build pavement roads.

Purpose: The purpose of the test is to measure the homogeneity of concrete. Many factors are taken into account when meeting the specific requirements of concrete strength, and to ensure that a homogeneous cement mixture is being used during construction. Tests also further identify the "ease of construction" of concrete, which provides a scale for how easy it is to transport, compact, and maintain concrete. then change the concrete mix by adjusting the ratio of cement-water or adding plasticizer to increase the slump of the concrete mixture.

Method of implementation: The concrete slump test proves many technological advances, and some countries even perform experiments using automated machines. Simplification, generally accepted methods of conducting experiments are as follows:

Testing equipment:

- Taper slump test

- Hard, flat, clean baseplate

- Compact, round steel rod, 16mm diameter, 600mm long, round tip.

- Accurate to 0.5cm

- Patch contact, fly

Steps to take:

+ Pour the 1st layer concrete about 1/3 of the height of the cone.

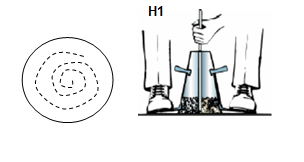

+ Using stick to poke evenly 25 pieces throughout the depth, poking from around the cone to the center (H1)

+ 2nd class,

+ Poke the following layers through the previous layer 2-3 cm (H2, H3)

+ 3rd layer, just poke and add more concrete to the mixture is always fuller mouth.

.png?1571216768873)

+ After finishing the 3rd layer, use a stick to swamp by the cone from the center to 02 sides and clean the concrete around the bottom of the cone (H4)

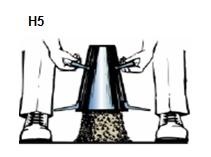

+ Use your hand to tighten the clutch onto the sole and then drop your feet from the pillow.

+

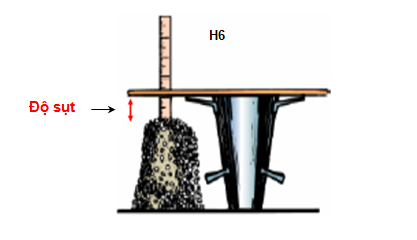

+ Place taper next to mortar shaped concrete block

+ Measure the height difference between the conical mouth and the highest point of the mixed mass, to the nearest 0.5 cm (H6)

+ Measured distance is the slump of the concrete mixture

Attention:

- The time from pouring a concrete mixture to the cone until the time of lifting the cone from the mixture shall not exceed 150 seconds.

- If after lifting the cone and the mixture block fall, a new concrete sample shall be taken for retest.

- The value of slump of concrete mixture is rounded to 0.5 cm.

Other news

Currently, ready-mix concrete is a top choice for many construction projects—both large and small—thanks to its convenience, consistent quality, and high construction efficiency. With extensive experience supplying commercial concrete for numerous key projects in the Southern region, SMC proudly offers a diverse range of ready-mix concrete products to meet the technical requirements of every type of construction.

A Comprehensive Guide to Concrete Specs – Everything You Need to Know

A Complete Guide to Concrete Specs – a set of technical parameters including concrete grade, slump, compressive strength, aggregate size, and mix ratio. This article helps you understand how to define, apply, and control concrete quality according to TCVN standards and practical construction conditions.

Comparing Ready-Mix Concrete, Lightweight Concrete, and Ultra-Lightweight Concrete: Which Is the Optimal Choice for Your Project?

Precast concrete box culverts are the optimal solution for drainage systems. Discover the structural standards and practical applications in SMC's article.