Frequently asked Questions

Concrete engineering advice

Business contact

How concrete is made

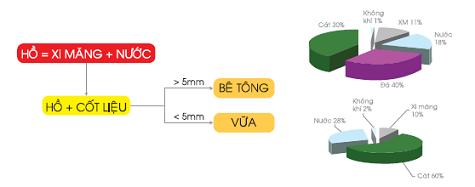

In simple terms of the concept of concrete, this material is a mixture of glue and materials. Adhesive consists of portland cement and water, which helps to link raw materials (stone, gravel ...) and fine materials (sand, grit, crushed stone ...). Through a chemical equation called hydration, these substances harden and cause all to stick together into a rock-hard mass.

In this process, the key leads to a remarkable property: the concrete is tough to mix and hard to cure. These properties explain why a material like concrete can build skyscrapers, bridges, sidewalks, highways, and traffic structures.

The key to achieving a sustainable concrete block in accordance with the concept lies in the meticulous division and mixing of concrete components. A sample without cement powder to fill the gaps between the rock sand will be difficult to place and create a rough surface. A sample with a large amount of cement powder will easily be laid and create a smooth concrete surface, however, this does not work and can easily crack.

The chemical properties of portland cement are only really useful in the presence of water. Mix cement and water according to certain standards to form a substance to help bind rock and sand. Through a chemical equation called hydration, the substance hardens and forms a solid concrete mass.

The strength of the adhesive will determine the properties of the concrete. The strength of glue, in turn, depends on the ratio of water and cement. The water-cement ratio is the weight of water mixed by the weight of cement. Lightweight concrete is produced by reducing the ratio of water-cement as much as possible without losing the construction ability, allowing concrete to be placed and fused properly.

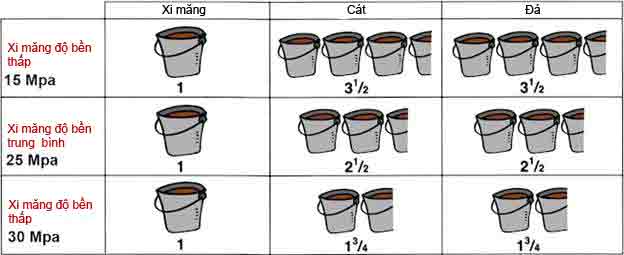

A properly designed concrete sample will have good construction capacity and the required strength and strength. Typically, a concrete sample will have about 10 to 15 percent cement, 60 to 75 percent sand and 15 to 20 percent water. The air in contact with the concrete surface can also account for 5 to 8 percent. Depending on the use, the composition and weight will produce different types of concrete suitable for each need and purpose of use.

Nearly any odorless natural water source can be used as a concrete mixing water. Excessive impurities in mixing water can not only affect the curing time and strength of concrete materials but can also cause blooming, honeycomb, staining, eating. wear reinforcement and reduce the durability of concrete. Specifications typically set limits for chlorides, sulfates, alkalis, and solids in mixing water unless tests have been performed to determine the extent to which the impurities present in the mixing water on the calf are affected. cardboard.

Although most types of drinking water are suitable for mixing concrete, they must be carefully selected. The raw material usually accounts for 60 to 75 percent of the total weight of cement. The type and size of raw materials depend on the thickness and purpose of the product.

The relatively thin construction requires small coarse aggregate, although aggregates up to six inches in diameter have been used in large dams. Continuous change of particle size is desirable to use adhesive effectively. In addition, the material must be clean and without any problems that may affect the concrete structure.

As soon as the materials, water and cement are combined, the concrete will harden. Most portland cement is hydraulic cement and will harden through a chemical equation called hydration. In this reaction, a node is formed on the surface of each cement particle. The node grows and extends until it binds to the button from other cement particles or adheres to adjacent materials.

Once it is thoroughly blended and usable, it will be placed in molds before the concrete becomes too hard.

During the installation process, concrete reinforces to compact within the molds as well as eliminate potential gaps, such as honeycomb.

For sheets, the concrete stays where it is until the moisture on the surface disappears, then a wooden or metal float is used to flatten it. The flattening process will create a solid but slightly rough concrete structure, with good slip resistance. If the surface is smooth, hard and thick, then proceed to the next process is steel forehead.

The maintenance will take place after the concrete surface is hard enough to resist chemical corrosion. Cultivation ensures the continuous hydration process of cement to enhance continuous hardness. Concrete will grow by spraying or using moist cloth such as silk or cotton towels. Other cultivation methods to prevent evaporation of water by sealing surfaces with plastic or unique spraying substances called cultivation compounds.

The technique is used for concrete in extremely cold or hot weather for curing. This will help the concrete retain moisture longer, become stiffer and more durable when it is finished. Hardening rate depends on the composition and fineness of cement, mixing ratio, moisturizing conditions and ambient temperature. Concrete will continue to be stronger from time to time. Most hydration and solidity over time will occur strongly during the first month of the concrete life cycle, but hydration will continue at a slower rate for the following several years.

Other news

Currently, ready-mix concrete is a top choice for many construction projects—both large and small—thanks to its convenience, consistent quality, and high construction efficiency. With extensive experience supplying commercial concrete for numerous key projects in the Southern region, SMC proudly offers a diverse range of ready-mix concrete products to meet the technical requirements of every type of construction.

A Comprehensive Guide to Concrete Specs – Everything You Need to Know

A Complete Guide to Concrete Specs – a set of technical parameters including concrete grade, slump, compressive strength, aggregate size, and mix ratio. This article helps you understand how to define, apply, and control concrete quality according to TCVN standards and practical construction conditions.

How to check the concrete slump

In construction and civil engineering, concrete slump test (or simple slump test) is the work performed at the construction site or in the laboratory that usually determines and measures the hardness, consistency of samples. Concrete before pouring concrete or casting maintenance, research or experiment samples.