Frequently asked Questions

Concrete engineering advice

Business contact

Note pouring fresh concrete in hot weather

Vietnam is a country with a tropical climate, which directly affects the construction process and concrete quality. Especially in the summer, rising temperatures greatly affect the construction process of pouring fresh concrete for buildings. Therefore, the article would like to share to readers some notes about pouring fresh concrete in hot weather.In hot climates, the workability of the concrete mix will decrease quickly, resulting in a more difficult construction process. Adding water to the concrete at the site to improve the situation, although it has been recommended to be dangerous, is still used. The extra water at the site will increase the water / cement ratio, reducing the intensity and durability of concrete.

To ensure the degree of reduction of intensity of concrete construction materials caused by hot weather within the permissible limits. The temperature of fresh concrete should be strictly controlled. At some projects in Vietnam require, the initial temperature of fresh concrete should be from 30 - 32 o C.

In addition to reducing the strength and durability of concrete, high initial temperatures of fresh concrete also lead to some negative effects:

- Making the hydration process of cement take place faster is the cause of premature hardening concrete - leading to the rapid reduction of the workability of concrete.

- The surface of the concrete dries very quickly, especially under the effect of wind, sunlight and relatively low humidity.

- To avoid dehydration, concrete needs to be cured or sprayed continuously on the surface. If dehydration occurs, cracks appear due to plasticity. In addition, the above process leads to the fact that cement cannot be fully hydrated. Further reducing the final strength of the outer concrete layer which was soon dehydrated. Reduce durability of concrete.

Initial control method of fresh concrete

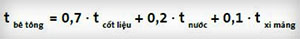

The formula for calculating the initial temperature of fresh concrete (concrete) is set roughly as follows:

Based on the above calculation formula, we realize that controlling the temperature of aggregate and water is the most effective method to control the initial concrete temperature.

Method of reducing the temperature of fresh concrete

- Cool aggregate by covering it here and moisturizing the aggregate

- Use ice during mixing / using water chiller

- Cool concrete mixture with liquid nitrogen

Plan to prepare concrete construction

- The process of concrete supply must be closely combined with the concrete construction process to minimize the delayed pouring.

- There must be adequate preparation of equipment and labor so that concrete can be bent and rammed quickly.

- The foundation and formwork must ensure not to absorb water from concrete. Formwork should be moistened before placing concrete. But precautions must be taken to prevent too much water from the mold and the floor causing condensation.

- If the conditions to be constructed in hot weather cannot be met, the construction should be postponed until the weather is cooler during the day. For example: construction at night.

- The setting hardening admixture can be used to reduce the disadvantage of hydration cement quickly, but they will extend the setting time of concrete a little. The use of extended-setting admixtures also requires prolonged curing time as they increase the risk of the occurrence of cracks due to plastic shrinkage. The foundation and formwork must ensure no water is drawn from the concrete. Formwork should be moistened before placing concrete. But precautions must be taken to prevent too much water from the mold and the floor causing condensation.

- If the conditions to be constructed in hot weather cannot be met, the construction should be postponed until the weather is cooler during the day. For example: construction at night.

- The hardening prolonging admixture can be used to reduce the disadvantage of rapid hydration cement. They will extend the setting time of concrete a little. The use of extended-setting admixtures also requires prolonged curing time as they increase the risk of the occurrence of cracks due to plastic shrinkage.

When is it allowed to dismantle the formwork?

Only formwork can be removed when the concrete structure has reached enough material strength to stabilize the structure. Usually people often consider the time from 3 to 4 weeks wrong when pouring in normal conditions (20 - 30 ° C) is enough to unload formwork, but if possible, the conditions for as long as possible.

There have been many cases due to dismantling of formworks before the prescribed time limit which caused the collapse of components and caused serious accidents. After dismantling the formwork, it should be noted that the commercial concrete only reaches the load-bearing strength (that is, the weight itself), but it will take a long time to work (the weight of the items). In case it is required to dismantle the formwork early, it is recommended to continue supporting components such as floors, beams and girders with wooden or metal supports.

Other news

Currently, ready-mix concrete is a top choice for many construction projects—both large and small—thanks to its convenience, consistent quality, and high construction efficiency. With extensive experience supplying commercial concrete for numerous key projects in the Southern region, SMC proudly offers a diverse range of ready-mix concrete products to meet the technical requirements of every type of construction.

A Comprehensive Guide to Concrete Specs – Everything You Need to Know

A Complete Guide to Concrete Specs – a set of technical parameters including concrete grade, slump, compressive strength, aggregate size, and mix ratio. This article helps you understand how to define, apply, and control concrete quality according to TCVN standards and practical construction conditions.

How to check the concrete slump

In construction and civil engineering, concrete slump test (or simple slump test) is the work performed at the construction site or in the laboratory that usually determines and measures the hardness, consistency of samples. Concrete before pouring concrete or casting maintenance, research or experiment samples.